Material flow

- Less search time, more efficiency – for clear structures along the entire process chain

- Modular systems – can be flexibly combined with other ORGATEX components

- Smooth material flow – for efficient, lean and structured production processes

Material flow

186 products

Showing 1 - 24 of 186 products

Material flow

ORGATEX offers innovative and customized solutions to optimize your material flow. The various Products, including for example Floor roller,Taxi car or shelf trolleys for the Material transport, are designed to meet your company-specific processes and to efficiently and sustainably improve both the handling and processing of products as well as the system-related interfaces.

The use of these solutions leads, for example, to a reduction in waste and Improving results in production and manufacturing. This saves you time and resources – a key factor for the competitiveness of companies in the industry. Learn more about material flow and how our solutions can help you save up to 30 percent of production costs.

What is meant by material flow?

When it comes to material flow, a distinction is made between external and internal material flow.logisticsIt is about the planning, management and control of internal and external material flows.

Theinternal material flowMaterial flow, on the other hand, consists of material transport and material provision and focuses on technical, economic, and organizational transport. Material flow involves the movement of materials, raw materials, and products within a company.

This process includes all steps that are technical, economic and organizationaltransportare necessary to transport, store, and process materials from one point in the production process to another. The following aspects are part of the internal material flow:

- Goods receipt

- storage

- Intralogistics

- Production processes

- Goods issue and shipping

An efficient internal material flow is crucial for theProductivity and profitabilityof a company because it helps to minimize costs, shorten lead times and ensure product quality.

Through a precise analysis of the material throughput,Potential for improvement revealedInefficient processes can be eliminated with appropriate measures. Learn more about this topic and contact our consultants. We'll be happy to help.

Material flow in lean production

TheLean Productionor "lean manufacturing" is a concept of production and process optimization that aims to minimize waste and maximize efficiency in a company.

It was originally developed in the automotive industry, particularly by the Japanese car manufacturerToyota, and has since expanded to many other sectors in the industry.

The original approach of Lean Production includes sevenTypes of wastethat can occur in companies. These include unnecessary transport, high inventory levels, unnecessary travel and movement, waiting times, overproduction, faulty processes, and errors.

All sub-areas are related to theMaterial flowin the company. Efficiency in material flow and transport can be achieved primarily by optimizing the layout and individual workstations.

How to optimize your material flow

Before measures can be taken to optimize the material flow, a soundMaterial flow analysisrequired. This will reveal weak points in the material flow so that they can be eliminated.

You can document the results and present them graphically to obtain an overview and define the goals of the optimized material flow.

Following the analysis,Lean methods, such as Kanban or Scrum, can be implemented to ensure material flow with as little effort as possible. When optimizing processes, it is particularly important to involve your employees and make new methods tangible through training.

ORGATEXoffers tailor-madeSystemsand products that can be customized to your specific needs. Discover our range!

Optimize your material flow - with ORGATEX

The planning,steeringORGATEX's efficient solutions sustainably and effectively optimize the management and control of internal material flows. By improving material transport, weak points in the material flow are uncovered and eliminated.

Theinnovative solutionsORGATEX solutions enable the optimization of material flow and the elimination of inefficient processes with appropriate measures. For example, throughput times are reduced and excess inventory is minimized.

Innovative solutions for efficient material flow

With the innovative solutions from ORGATEX, your material flow will be designed efficiently. Material transport andProcess optimizationplays a crucial role. This includes systems that record these areas in your company and thus uncover weak points in the material flow.

A comprehensiveanalysisenables an effective and sustainable reduction in waste and leads to improved working conditions for your employees. To do this, you need to investigate the conditions on-site and take stock.

When planning the material flow, you can also define precise key figures and representations. This allows you to clearly see the connection between the individualProcesseswithin the material flow. Call us or send us an email. We'll be happy to advise you.

ORGATEX solutions for optimized material transport

Tugger trains can make material transport much more efficient and are therefore important for theCompetitiveness of companies. By floor rollers, shelf trolleys, taxi cars andAdapter palletsFor the transportation and provision of materials, throughput times can be reduced and inventory levels in the warehouse can be reduced. Learn more about our solutions for optimized material transport.

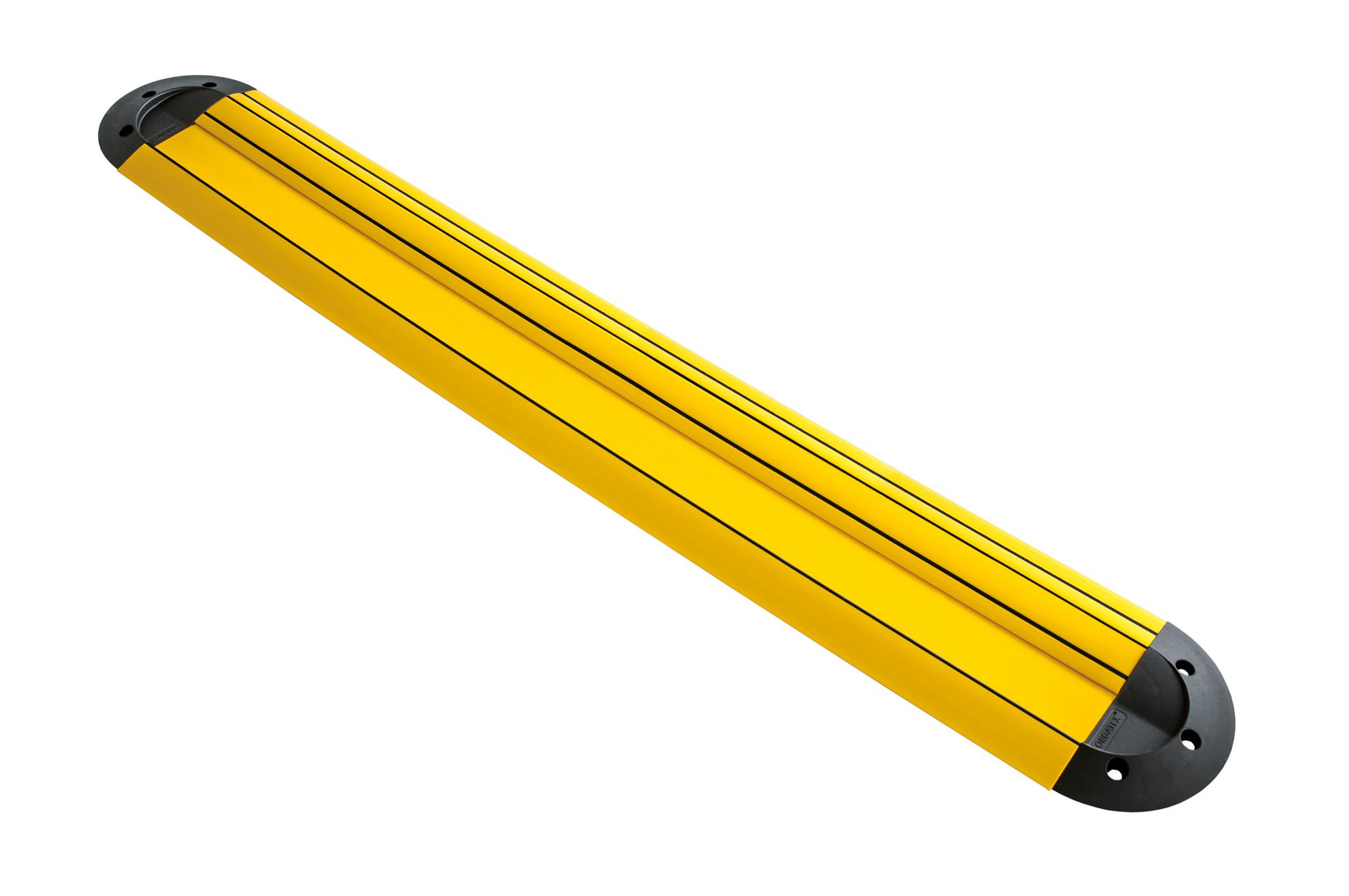

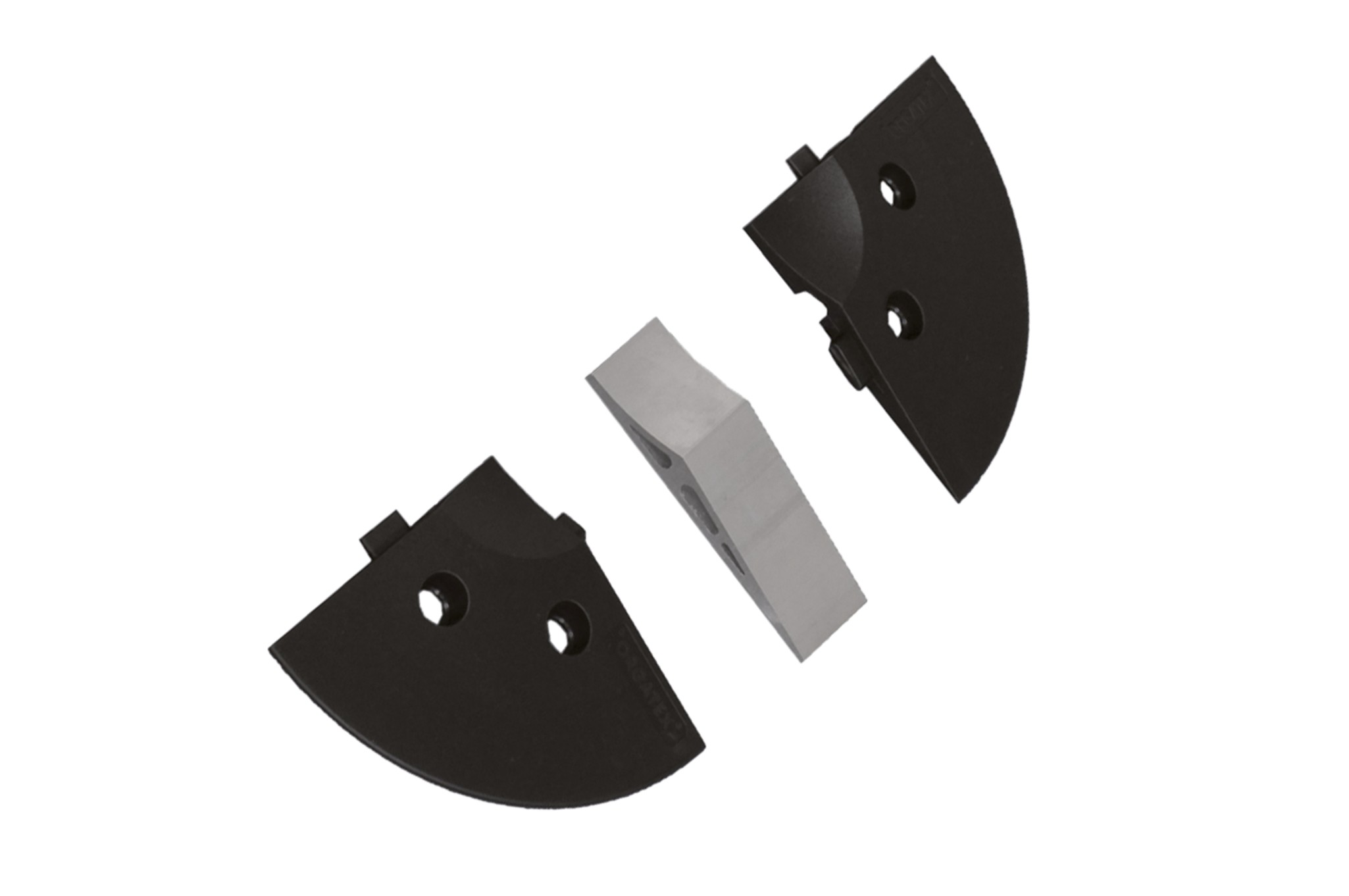

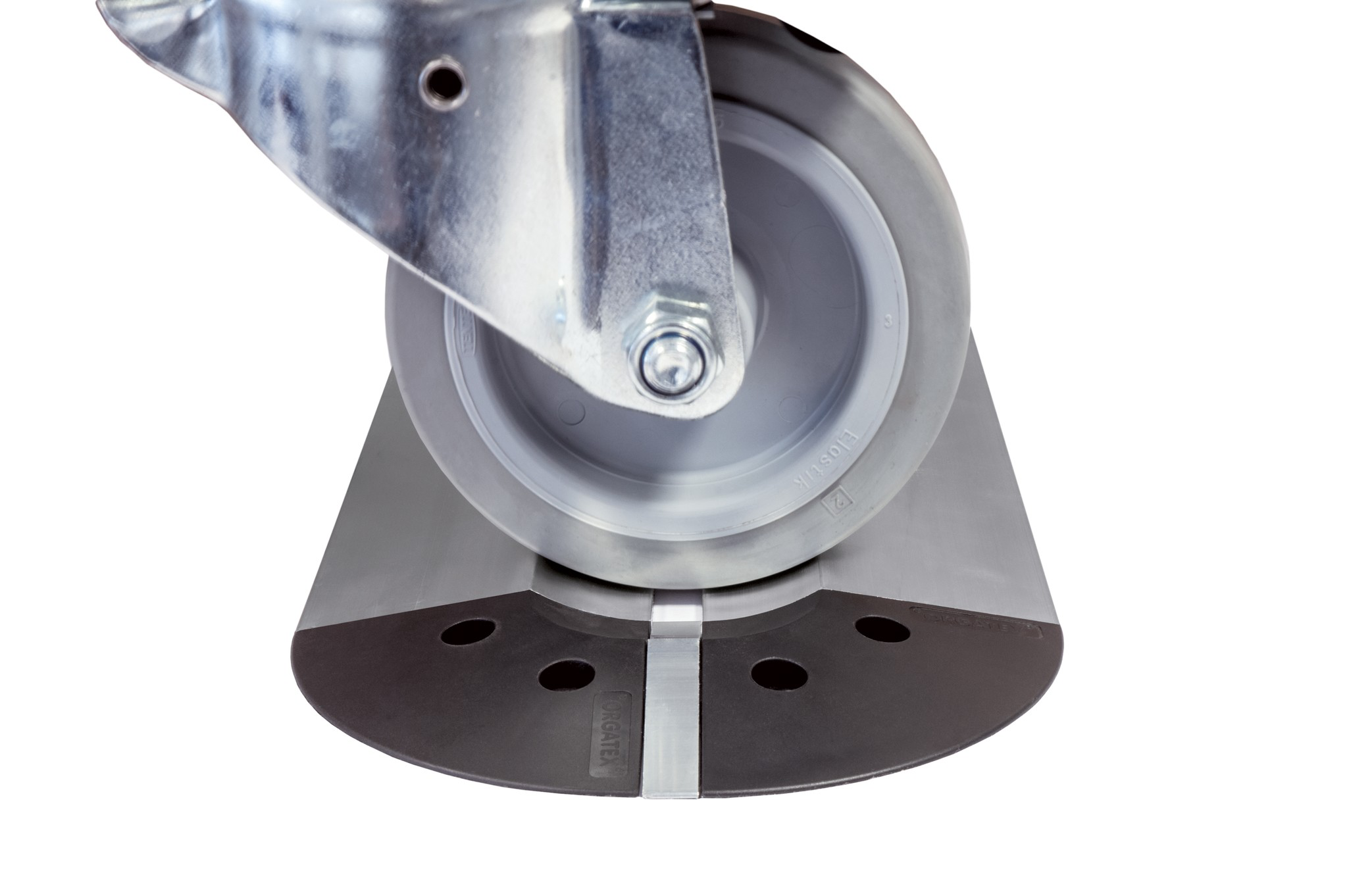

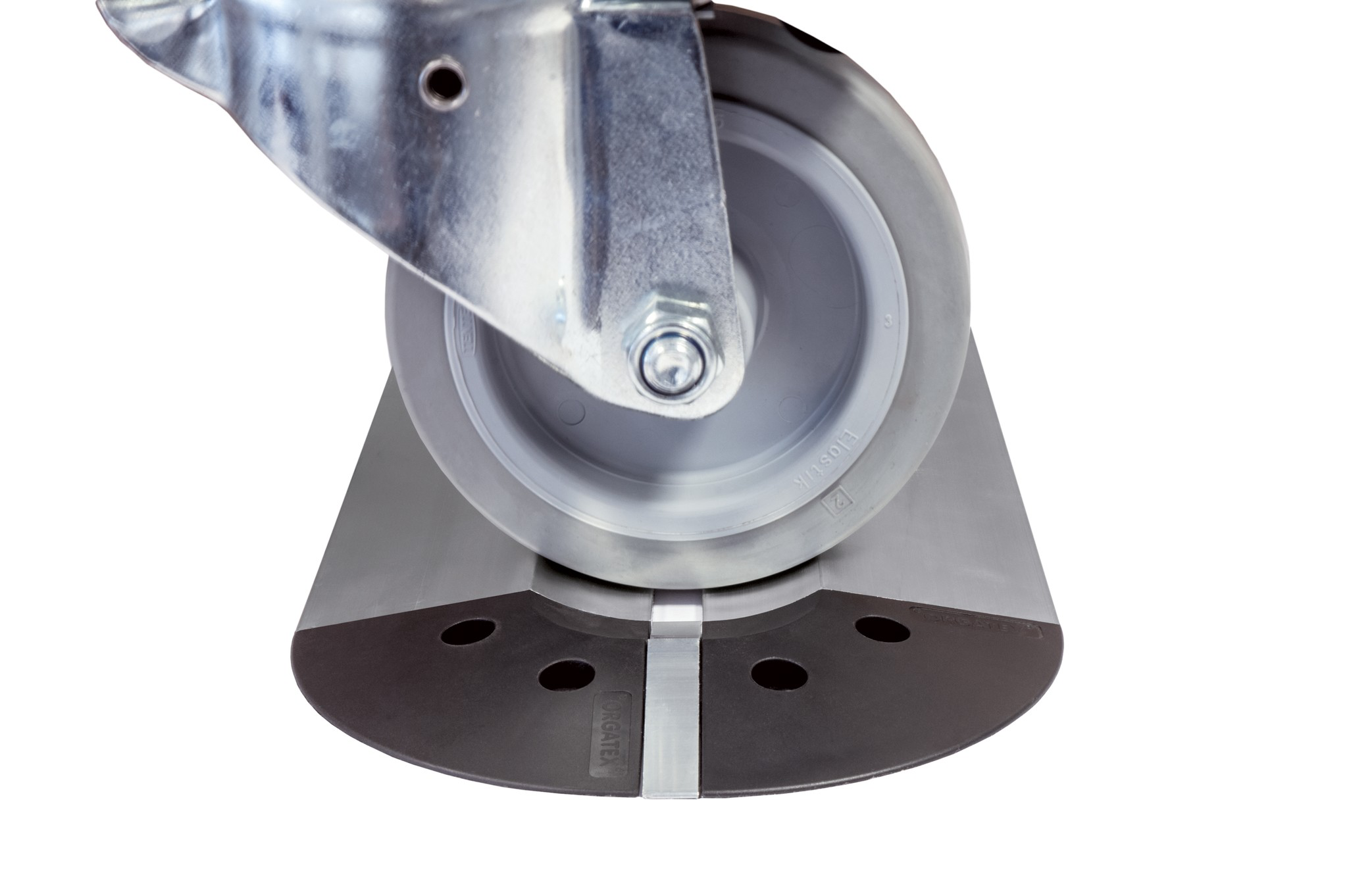

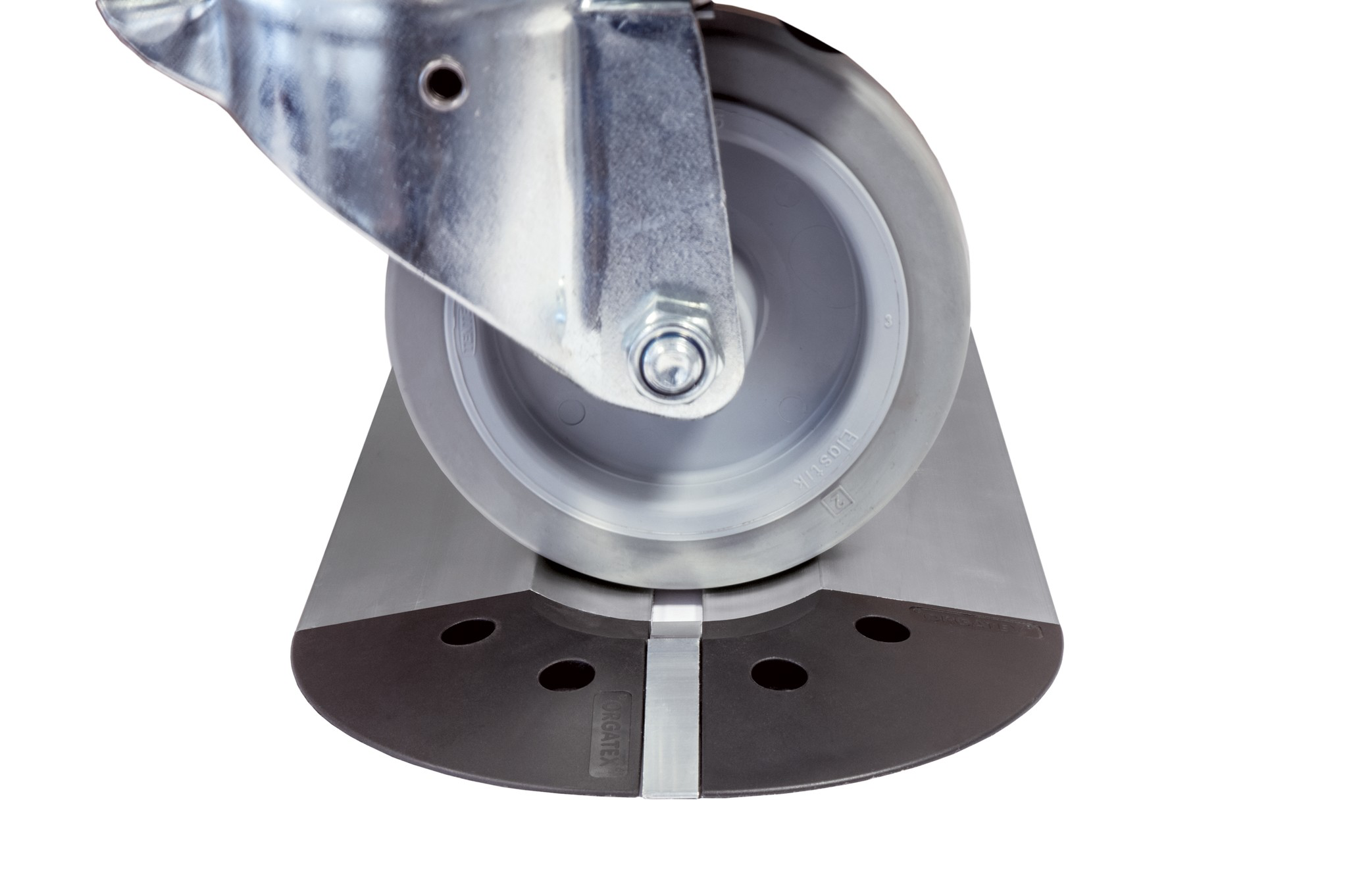

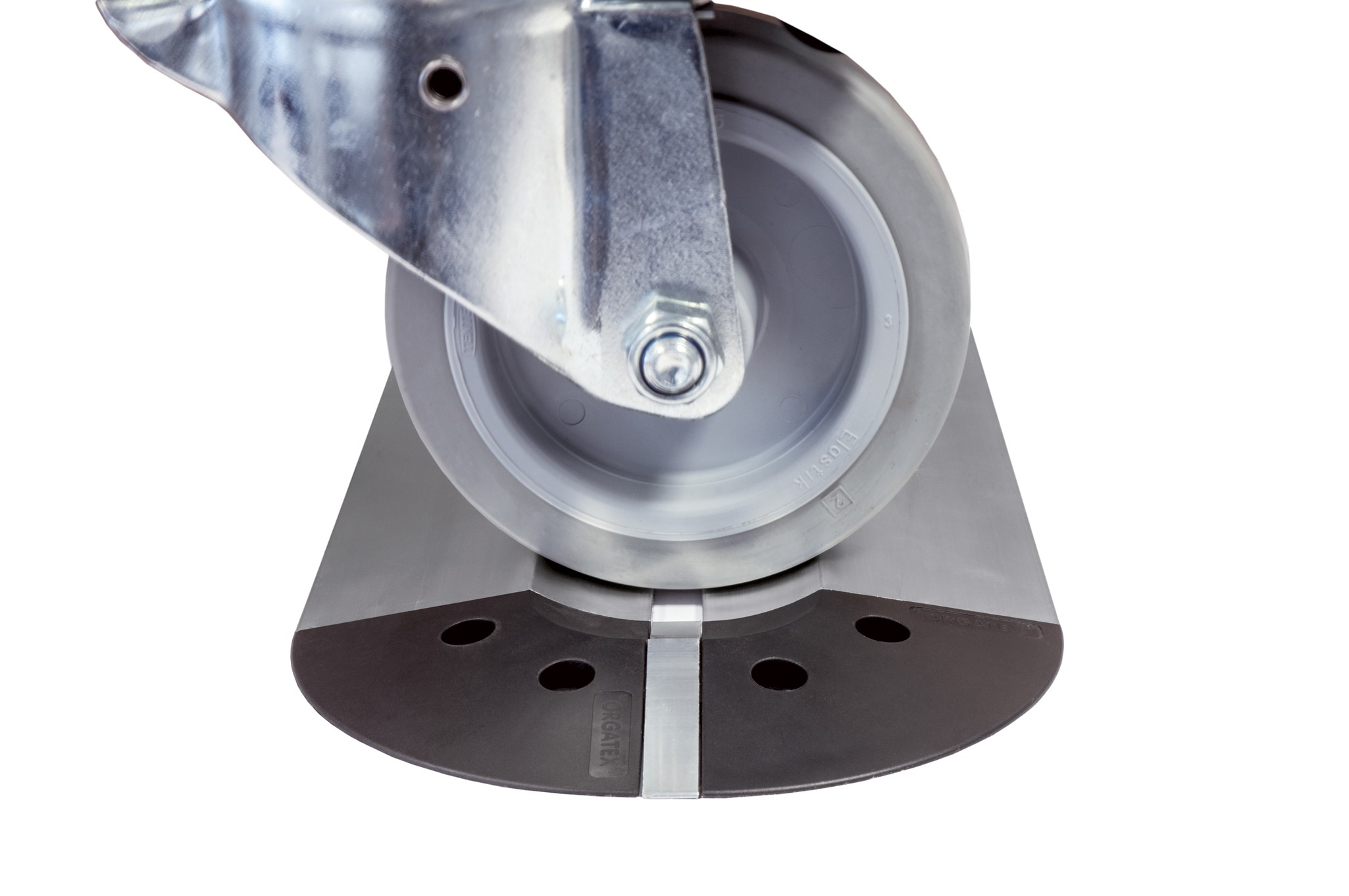

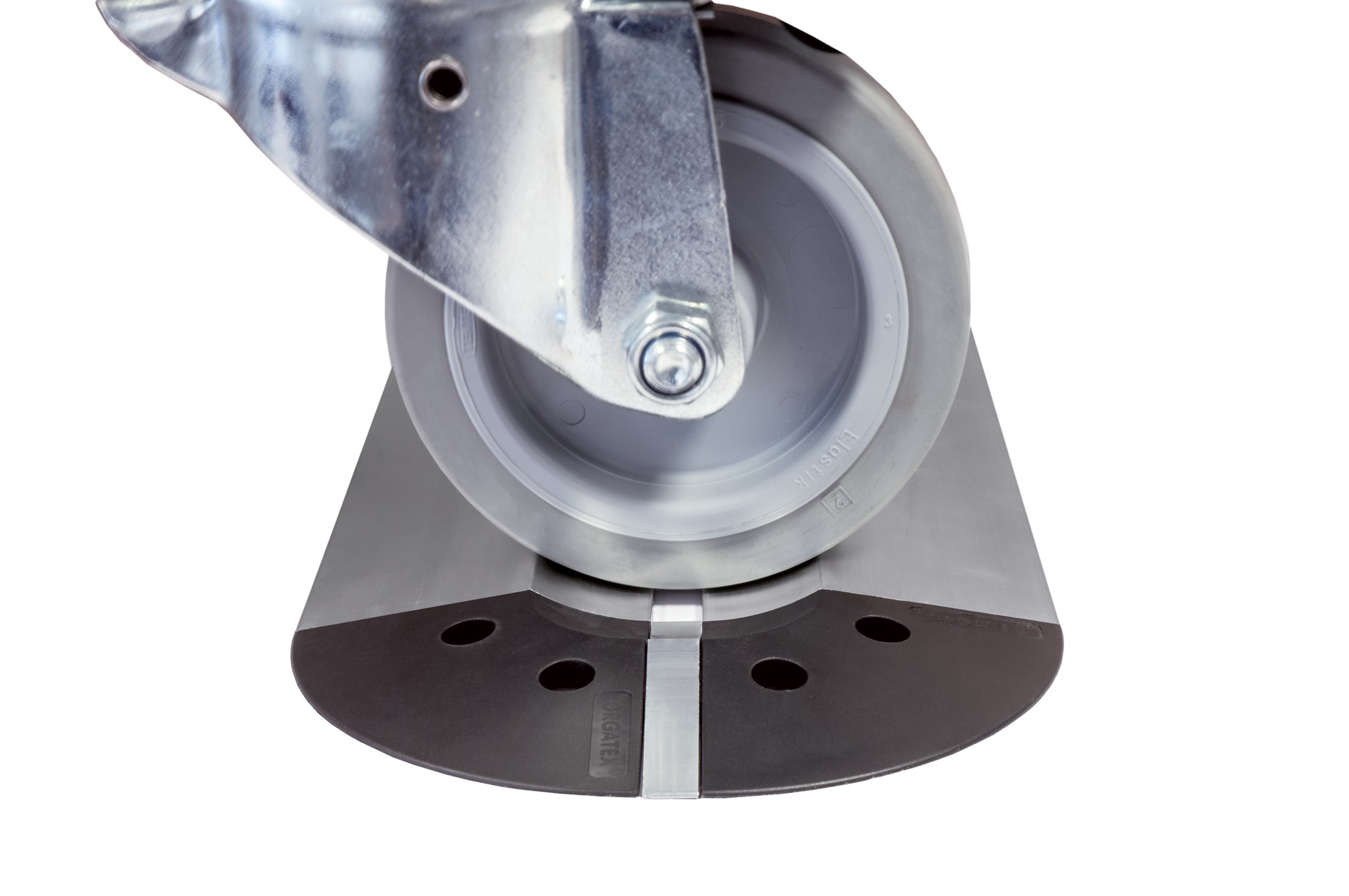

Use floor rollers for material transport

Stable floor rollers are an essential component for optimizing your material flow and form the basis for theMaterial transportFrom the receipt of goods, through production and manufacturing, to the delivery of the products to the supplier, floor trolleys are actively involved in all processes of the logistics chain.

They are an important component toProcesses in the companyto be more efficient. Unlike pallets, they require little space in the warehouse and can be transported quickly and without the need for a forklift.

By implementing ORGATEX floor trolleys, you can reduce material transport times and improve working conditions. A careful inventory of thematerial flowDirectly on site allows for in-depth analysis of technical, economic and organizational aspects.

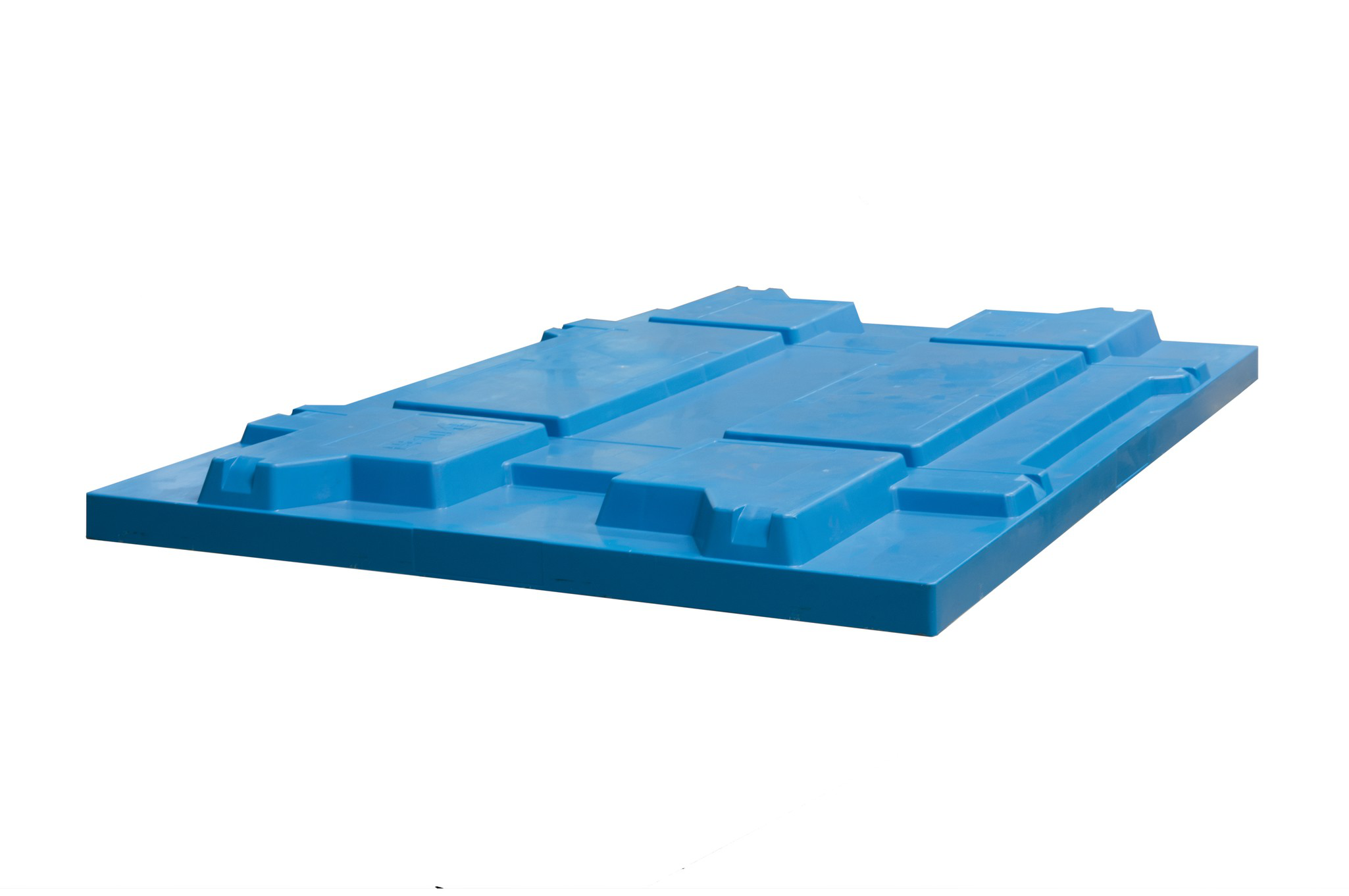

How adapter pallets improve your material flow

Adapter pallets are an innovative tool for improving your material flow. They play a crucial role in the control technology within a company. Their use allows floor trolleys to be stored and easily connected to theForkliftbe transported to the warehouse.

A thorough material flow analysis is therefore essential. Determining material throughput enables sustainable process improvements. With practical adapter pallets and floor rollers from ORGATEX, your material flow will be more efficient and your intralogistics will be sustainably optimized.

Improvement of working conditions, savings and acceptance

Improve your material flow with the innovative product series from ORGATEX in the area ofWorkstation systemsthat impress with their high-quality workmanship and robustness. Regardless of whether they areKlt-Lifteror assembly workstations, all products are designed to improve the material flow within your company and optimize processes.

Efficient material flow solutions through ergonomic workplace systems

Through the use of ergonomicWorkstation systemsthe material flow within a company is designed efficiently andProcessesin theMaterial provisionoptimized by saving unnecessary movements and time spent searching for tools and materials.

For example, they contribute significantly to improving assembly processes. Through a detailed review of products and material flow,Vulnerabilities uncoveredand deficiencies are eliminated with appropriate measures. ORGATEX workstation systems thus function as a crucial interface within the logistics chain and lead to sustainable efficiency and productivity in your company.

How KLT lifters make material flow in your company more efficient

The use of KLT lifters revolutionizes the material flow in your company. The lifter takes over the heavy lifting of crates for your employees and is fully adaptable to your needs. This protects theHealth and strengthYour employees and avoid downtime due to illness and overwork. Discover the helper that makes work easier!

Material provision based on the first-in-first-out principle

The provision of materials after theFirst-in-first-out principle (FIFO)is a method of storing and retrieving materials in which the materials stored first are also removed first.

FiFo is a system that prevents damage caused by longstorageThis prevents waste and enables easy traceability. Furthermore, required quantities of material can be precisely calculated and prepared for transport. Learn more about efficient distribution within your company.

FIFO stations for continuous material flow

ORGATEXFIFO stationscontribute significantly to the optimization of your internal material flow. They areessential system elementsof the material flow and support the effective distribution and transport of your products, raw materials and materials for production and manufacturing.

With a thorough inventory, our consultants record the current condition directly on site, identify deficiencies and offertargeted measures and methodsfor optimization. The meaningful results are carefully documented and graphically illustrated to provide a comprehensive overview. Increase your company's efficiency with ORGATEX!

Individual solutions for your material flow with ORGATEX

ORGATEX stands for intelligent solutions, outstandingvisual management,Securityandefficient material flowfor industry and production. Through a detailed on-site inventory, all processes within a company and related to the internal material flow are inspected.

ORGATEX's logistics concepts offer customized solutions to optimize your material flow. They focus on the system elements that are part of your company's internal processes. This includesin-depth material flow analysiswith on-site inventory and identification of system boundaries and interfaces.

With the help of appropriate measures, identified weak points in the transport and provision ofmaterialThis not only improves intralogistics processes but also optimizes the entire logistics area – for satisfied customers and efficient workflows.