FIFO stations

Which FIFO solution would you like to use: monorail or plastic station?

Supermarkets/FiFo stations

54 products

Showing 25 - 48 of 54 products

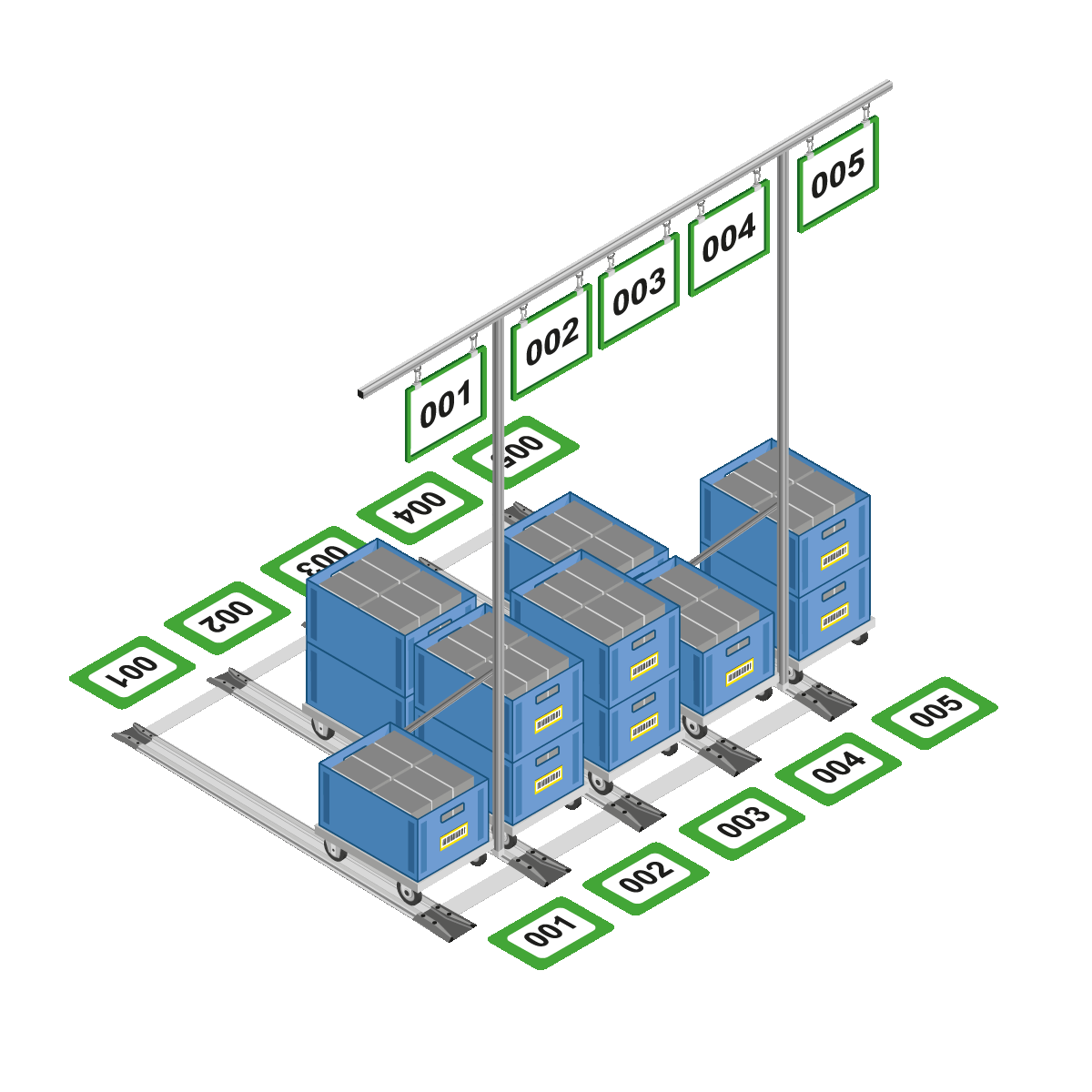

ORGATEX FIFO stations: the supermarkets for your floor trolleys

Large inventories tie up capital and time that your employees spend searching, they eat up time and money. Production In manufacturing, one thing is particularly important: keeping material stocks as low as possible and making processes transparent.

The FIFO principle helps to optimize material provision. FIFO stations are part of the Kanban provisioning system. Supermarkets for Floor roller and material carts. This means that your production or manufacturing employees remove the appropriate material carts or floor rollers from or into the FIFO station as part of the control loop.

The FIFO station is similar to the principle of a supermarket, where customers can take the desired goods from the shelves themselves and without any further effort.

What is a FIFO station?

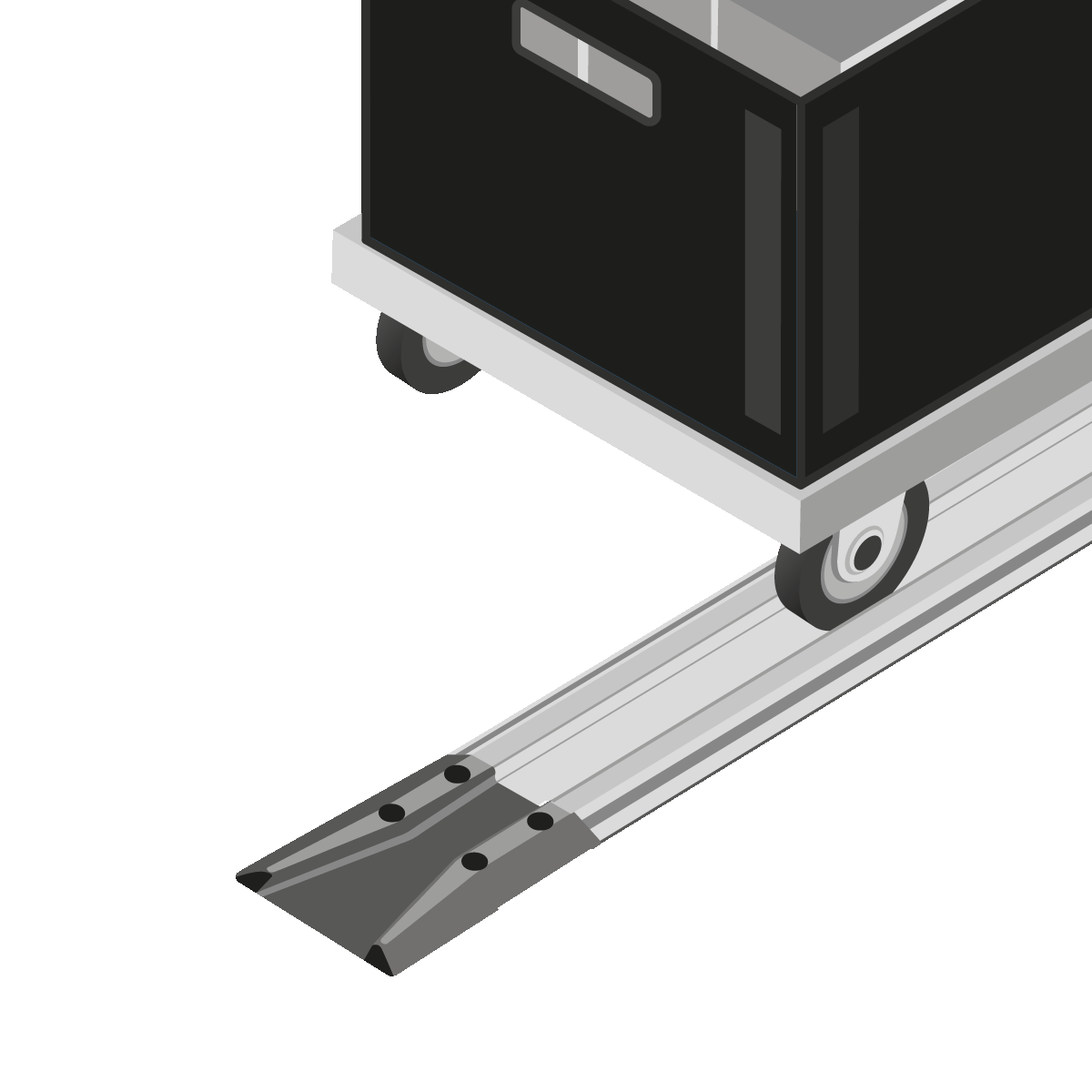

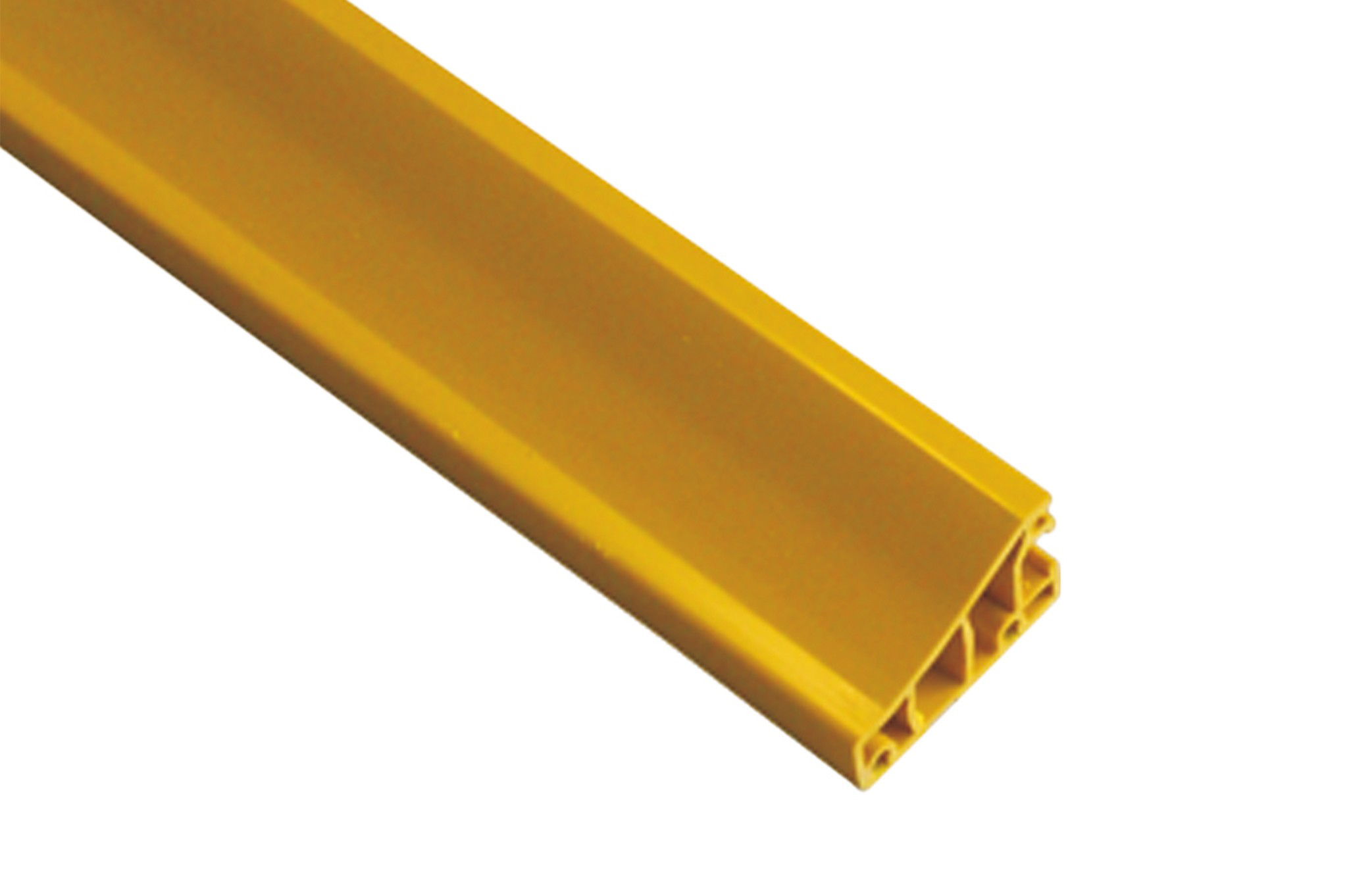

An ORGATEX FIFO station is a modular rail system for floor rollers or material carts. The system's guide rails are simple to set up, and the system can be flexibly expanded to meet changing needs. Similar to a train station, the carts are moved onto permanently installed rails and can be retrieved from the FIFO station by your employees as needed. The profiles on the FIFO station are self-adhesive, and the guide rail can be screwed to the floor. The guide rails and end caps are available in various designs, making them suitable for all roller widths of your floor rollers or standard material carts, and their design allows for flexible adjustment in length and width. Shelving systems can also be integrated into the system.

Supporting the 5-S principles in material provision

The FIFO station supports the 5S principles originating in Japan. These principles were developed by Toyota after World War II for the successful production of automobiles and are intended to prevent waste of resources by systematizing and optimizing workflows. The 5S principles were later adopted by many other companies, including:

Select

Sort

Clean

Standardize

Self-discipline

Part of the 5S principles is the placement of materials so that they are easy to find and access without obstructions. The FIFO station fulfills this goal. If your material, manufacturing, and/or operating costs are constantly rising, or you have persistent overproduction or excess inventory, the FIFO station could be the solution for efficiency and effectiveness in your company. Contact us; we would be happy to assist you.

Kanban provision with FIFO station: Benefits for your production

Kanban provisioning with the FIFO station ensures efficient and effective workflows. The system not only optimizes the use of material carts and floor rollers in material flow, but also has a positive impact on your entire company by saving time and resources in the long term. The advantages at a glance: clear design and standardization; clear visualization and transparent processes; clear structuring of material provision; quick retrieval of materials; easily traceable errors or disruptions in the process; space-saving, modular system.

The FIFO principle: First in first out

The idea behind the FIFO principle is quite simple: first in, first out. This means that the products, goods, or materials that arrive at the station first in the material trolley are also the first to be used and leave the station again. The transparency of the system is particularly advantageous when it comes to perishable products, such as food. Goods that are subject to certain seasonal or fashionable aspects can also be organized using it. This ensures rotation in the warehouse and prevents the depreciation of goods. At the same time, continuous inventory control is possible. The high level of transparency also benefits manufacturing and production. Long periods of time that your employees have to spend searching for material trolleys are avoided. The optimization provided by the FIFO station enables, for example, just-in-time production, where adherence to time specifications is particularly important.

ORGATEX: The partner at your side

Quality from a single source: Optimize your material supply with our solutions and discover our offerings for visual management in compliance with legal requirements and efficient transport solutions for your company, or our modern solutions for digital intralogistics. Do you need help converting your production or manufacturing lines to Kanban supply? If required, we would be happy to create a complete FIFO station system for you. We are available to answer all your questions regarding the organization and safety of your hall or warehouse and are happy to advise you and consider your individual needs and requirements. Contact us today.